In the post-implementation phase of projects implementing standard OEE metrics, new customization metrics will typically emerge to meet specific business needs. Required modifications can be found at the level of data collection, calculation of indicators, analysis of results or control of related processes. Now let's look at modifications to the OEE metric that can be used to evaluate and reward staff.

Derived OEE indicators

In the article OEE and derived indicators TEEP, PEE, OAE, OPE, OFE, OTE and CTE we looked at the derived OEE indicators. Some of the indicators will be followed by the topic of personnel rewarding, so we will briefly repeat them now.

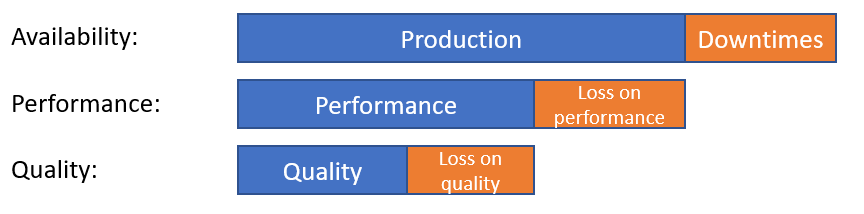

PEE - the main difference of PEE (Production Equipment Efficiency) lies in the weights of the sub-indicators (Availability, Performance and Quality). While for OEE all sub-indicators have the same importance, for PEE the importance of the sub-indicator is given by the set weight.

The method of PEE calculation also varies according to the type of production (discrete and continuous). For discrete production, the sub-indicators remain the same as in the case of OEE, only the weights of the individual indicators are added:

PEE = (Availability)k1 x (Performance)k2 x (Quality)k3, where “ki” is the weight of “i”, 0 < ki ≤ 1, ∑ki = 1

See the article OEE and derived indicators TEEP, PEE, OAE, OPE, OFE, OTE and CTE for more info.

We can use indicator weights, for example, if we prefer one of the OEE components when evaluating staff. If different groups of workers have different effects on the results of individual indicators (operators on quality, setters on performance, shift leaders on utilization, etc.), we can use calculations with different weights to evaluate these groups.

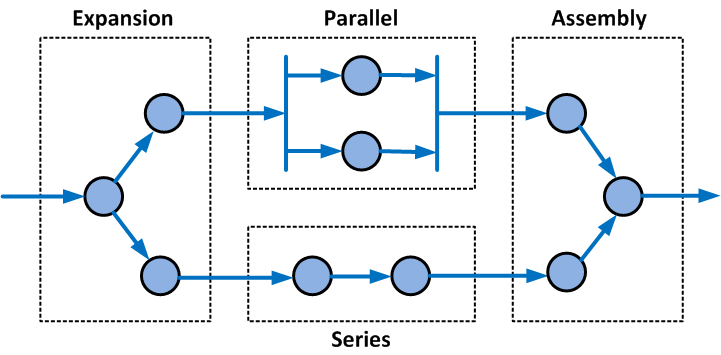

OFE (Overall Factory Effectiveness) methodology is used to express the efficiency of the whole production company. If there are multiple production steps on multiple devices in a production, classic OEE cannot be used at the enterprise level. While OEE focuses on the efficiency of individual devices, OFE evaluates all devices together. It includes relationships and interactions between different devices and processes in the calculation.

The production environment consists of subsystems that can be divided into 4 basic groups:

- Series (serial, in line)

- Parallel (parallel, concurrent)

- Assembly (joining, montage)

- Expansion (separation, expansion)

It is possible to model the whole production flow with these 4 groups. The metrics like OTE (Overall Throughput Effectiveness) or CTE (Cycle Time Effectiveness) then evaluate the effectivity of individual subsystems.

OTE expresses the ratio between actual output and theoretically possible output. The methodology is closely linked to simulation techniques for increasing production productivity. CTE is then the ratio between the theoretical cycle length and the actual cycle length.

If there are no complicated relationships and interactions between different production facilities and processes in production, we can be satisfied with some elementary aggregation method:

- Arithmetic mean - simple arithmetic mean

- Modus - the most common value, the modus of discrete or continuous random variable

- Median - middle value

- Minimum - minimum value, bottleneck of the production process

- Maximum - maximum value

- Weighted arithmetic mean - for each of the partial indicators the weight can be a different number

- Harmonic average - average production speed ...

- Geometric average - average growth rate ...

A special case of the elementary aggregation method is the so-called Composed Equipment, which represents a group of production equipment that we consider as one production equipment implementing parallel production.

Aggregation methods will be used to calculate OEE over various objects (specifically through groups of devices), see chapter 4 - Objects for OEE evaluation.

Staff evaluation according to OEE

Accurate production efficiency information gained from the deployment of OEE tools opens the way for the evaluation of personnel according to the achieved OEE values.

The use of OEE for staff rewarding and evaluation brings:

- Systematic approach - measurement and evaluation is carried out regularly, automatically and transparently according to established rules

- Measurable criterion - hard KPIs

- Comprehensive evaluation - compared to, for example, quality evaluation, which is just one of the OEE parameters

- Teamwork attitude – the reasons for OEE decrease can not be usually linked to just one person, it is usually a group of persons (operators, setters, handlers, shift leaders, planners...)

Application of OEE in management methodologies

OEE can be embedded in established methodologies for staff evaluation and management:

MBO - In the MBO (Management by Objectives) method, OEE indicators can be treated as targets. The method described by Peter F. Drucker (The Practice of Management, 1955) is based on setting and agreeing goals and evaluating the success of achieving them. OEE fulfills the main aspects of this method:

- Goal setting - setting of OEE target values for given workplaces, products, orders, etc.

- Introduction to objectives - publication of OEE target values (at operator terminals, visualization panels, intranet, ...)

- Goal monitoring - automated real-time evaluation and alarm of OEE development

- Familiarization with the fulfillment of goals - publication of achieved OEE values (at operator terminals, visualization panels, intranet, ...)

- Provide comparisons - along with the OEEs achieved, the required comparisons are made available in real time

This comparison is done in relation to:

- The target goals

- Groups (and among them)

- The evolution over time

Analysis of causes of OEE decline

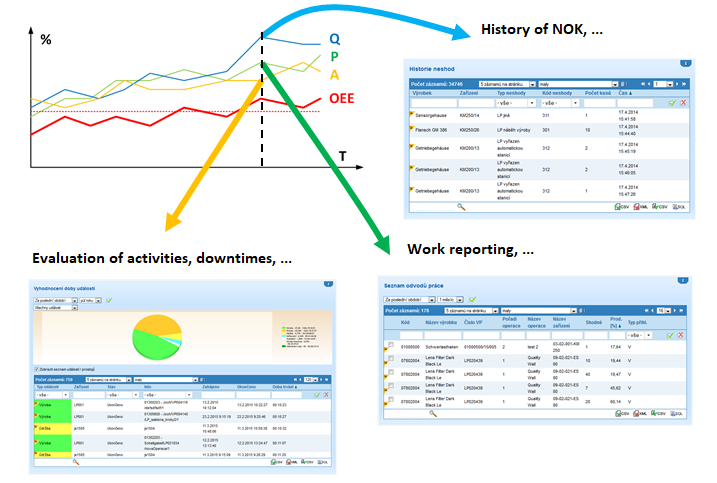

Thanks to its sub-indicators, OEE can identify areas where efficiency has declined. Employees are presented not only the overall results of OEE, but also the results of the sub-indicators Availability, Performance and Quality. In addition, workers should be able to break down Availability, Performance and Quality indicators into individual factors. The disintegration of the Quality indicator is in practice realized, for example, by a list of individual occurrences of non-conforming pieces in the period in question. The performance indicator can be a list of individual workflows and the availability indicator can be a list of events and downtime on the machine.

Objects for OEE evaluation

While the standard OEE metric evaluates the efficiency of a single production facility or group of production facilities, for personnel evaluation it is necessary to relate the calculation to a given person, group of persons, shift or production order or product.

Manufacturing companies most often require breakdown of OEE over following objects:

- Product / Production Equipment

- Product

- Production Order / Production Equipment

- Production Order

- Person/ Production Equipment

- Person

- Group of persons / Production Equipment

- Group of persons

- Shift / Production Equipment

- Shift

Or other combinations of the objects above:

- Shift / Production order / Production Equipment

- Shift / Product / Production Equipment

- ...

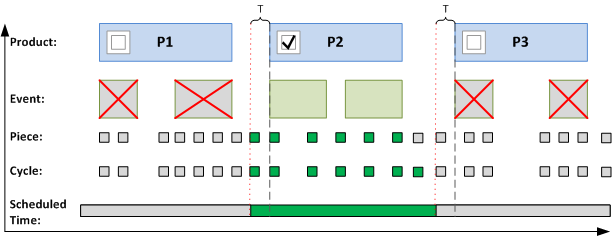

While in the standard OEE calculation, the availability of the production equipment is straightforward, for calculations performed through the above objects, intervals that are not directly related to the objects must be addressed.

For example:

- To which product belongs the downtime caused by re-setting the machine for another production?

- To which person belongs the production taking place at the time of staff rotation? To the original operator,

to the new operator, or both? The alternation events may be interconnected, overlapping, or may there be a gap between them?

To solve the above and other similar situations, it is necessary to specify and set rules that will be applied to the calculation of given intervals (how to include intervals in the calculation, to which objects to bind intervals, how long to bind intervals, etc.).

Furthermore, we must ensure that the activities taking place at these intervals are properly recorded. For example, to distinguish activities falling to the end of one production from those that start the following production.

If the view exceeds one production facility (e.g. production efficiency of a given product through a group of selected production facilities), then it is also necessary to proceed to one of the aggregation methods, see Chapter 1 - Derived OEE indicators.

Separation of the human and the machine factor

The described methods of personnel evaluation are based on the overall efficiency of the production equipment, which is based on both human and machine factors. In most cases, both factors play a significant role. Even in fully automated operations, the production process is intervened by personnel - for example, as maintenance. The machine factor can then be minimized in purely manual operations. However, a large number of assembly operations use different production equipment and hence the machine factor has an impact on workplace efficiency.

If we want to eliminate the machine factor and focus on the work of the operator when evaluating the personnel, we can use methodologies that can distinguish these factors.

OLE

OLE (Overall Labor Effectiveness) provides a separate look at the causes of efficiency loss caused by production equipment and production personnel. While OEE does not differentiate whether the decline in efficiency is due to production equipment or production personnel, OLE focuses on these differences, and in particular on staff efficiency.

The following examples describe situations where OEE does not distinguish the causes of the efficiency decline:

- Due to the current lack of qualified personnel, the machine cannot be re-adjusted. The machine shows downtime and OEE decreases. However, the cause of the drop is not due to the potential of the machine. This can be ascertained from the analysis of efficiency losses, but we will not reveal it in the overall OEE result.

- The machine shows satisfactory OEE values, but an excessive amount of service personnel is allocated for its operation. Low staff efficiency is not reflected in the OEE result and is not covered by standard efficiency loss analysis tools as the situation does not translate as OEE loss.

The calculation of OLE is done according to the same formula as OEE:

OLE = Availability * Performance * Quality

Partial indicators of OLE are affected by different factors than in the case of OEE:

Availability

- Absence, vacation, sick leave…

- Trainings, meetings…

- Planning, downtime, shift change…

Performance

- Availability of instructions, tools, materials...

- Qualification, skills…

- Training, mentoring…

Quality

- Qualification, skills, knowledge, motivation…

Following instructions, correct usage of tools…

Conclusion

OEE is a metric designed to monitor the overall efficiency of each production facility. Its use for staff evaluation is a controversial topic. Nevertheless, manufacturing companies use the OEE metric to assess and reward personnel.

This article described derived OEE indicators that are either directly intended for staff evaluation or that have characteristics that can be used in staff evaluation. The article also mentioned the benefits of using OEE and the possibility of incorporating OEE into established personnel management metrics.

Miroslav Patočka

MES PHARIS Analyst

UNIS, a.s. | Control & Information Systems

Note: The graphics used in the article were taken from the system MES PHARIS.

English (UK)

English (UK)  Česky (CS)

Česky (CS)