Constantly winning new projects and taking the leading position in the production of sun visors sounds pretty tempting, doesn’t it? A sun visor a prestigious visual part, however, its design and production takes deep knowledge in many fields. LUKOV Plast managed to capitalize on long-term experience and they nowadays they manufacture sun visors according to the highest standards in the industry. They gradually optimized all production steps, starting from the initial preparation of semi-products all the way to the final assembly.

Together with Brno-based company UNIS, Inc. LUKOV Plast managed to implement successfully and with high efficiency the principles of Industry 4.0 in the Sun Visor project, while still maintaining the requirements of IATF 16 949. As the main process integration tool, LUKOV Plast used MES PHARIS, that covers not only MES standards (Manufacturing Execution System), but also MOM standards (Manufacturing Operation Management). MOM is like an MES boosted with Maintenance, Production Logistics and Capacity Planning & Scheduling capabilities.

Key project attributes

| Customer | LUKOV Plast spol. s r.o. | |

| Used solution |

MES PHARIS | as phar as it goes | |

| Supplier | UNIS, a.s. | Control & Information Systems | |

| ERP | SAP | |

| Production type |

Discrete | |

| Manufacturing areas |

Production monitoring and control, Quality, Production logistic | |

| Manufacturing classification |

Automotive, Electronics & Mechatronics, Plastic & Rubber | |

| Integration | ||

| Essential functionalities |

Control & Monitoring of Production, Production Logistics, Paperless Production, Production Traceability, Nonconforming Production Management, Production Quality Control, Process Data, Machine Data Collection, Performance Analysis, Production Visualization | |

| Year of realization | 2014 |

Main areas supported by MES / MOM system

Manufacturing of semi-products in the molding shop

There are currently roundabout 40 ENGEL Injection Molding Machines in LUKOV Plast. These machines provide one- and two-component injection molding. Two-component molding with minor metal insignia had to be utilized together with high-level robotization for the process of sun visor manufacturing. MES/MOM system provides complex electronical production management, monitoring and performance evaluation in the molding shop. This also includes collection of technological parameters from IMM, distribution of electronic production documentation, quality management, tool management and more… Production logistics also benefits from the implementation of MES in the company. Label printer is located directly at the workplace, which ensures seamless packaging unit identification. The risk of putting a product into an incorrect packaging (leading to a certain complaint) is minimized by MES-driven standardized production process.

There are currently roundabout 40 ENGEL Injection Molding Machines in LUKOV Plast. These machines provide one- and two-component injection molding. Two-component molding with minor metal insignia had to be utilized together with high-level robotization for the process of sun visor manufacturing. MES/MOM system provides complex electronical production management, monitoring and performance evaluation in the molding shop. This also includes collection of technological parameters from IMM, distribution of electronic production documentation, quality management, tool management and more… Production logistics also benefits from the implementation of MES in the company. Label printer is located directly at the workplace, which ensures seamless packaging unit identification. The risk of putting a product into an incorrect packaging (leading to a certain complaint) is minimized by MES-driven standardized production process.

Sun visor assembly lines – product controls the assembly process

The core concept of I4.0 is the idea that the product itself controls the production process, which is fully automatic. Therefore each sun visor body gets a unique QR code at the first operation. After reading this QR code, the assembly line gets automatically reconfigured according the product’s variant. MES system then uploads the pre-defined parameters into PLC control units and re-registers the operator to a corresponding contextual work order. The code of the product also carries a complex technical preparation of production, that is accessible through touch screens directly at the workplace.

The core concept of I4.0 is the idea that the product itself controls the production process, which is fully automatic. Therefore each sun visor body gets a unique QR code at the first operation. After reading this QR code, the assembly line gets automatically reconfigured according the product’s variant. MES system then uploads the pre-defined parameters into PLC control units and re-registers the operator to a corresponding contextual work order. The code of the product also carries a complex technical preparation of production, that is accessible through touch screens directly at the workplace.

MES system deals with following tasks at each production nod of the MQB assembly lines:

- Displaying of the currently approved production documentation and control of the production documentation change process. MES notifies operators about new changes in the documentation and requires their confirmation of reading the change record. The most important documents are presented as screensavers at the production terminals. Showing the production documentation in the form of a short video has recently become more popular due to its language independence. Instruction videos usually run on a secondary LCD monitor.

- MES prevents operators without proper training or with an expired training from registering to critical production operations.

- NOK piece classification is conducted manually by operators or by automatic control stations connected directly to MES.

- NOK workflow – the type of NOK is recognized by the system, it is also possible to classify input material as NOK, which enables the identification of non-conformal inputs from previous production processes, plus it refines the consumptions of input materials or semi-products.

- Control of inputs – MES checks the right type of input components. MES requires the operators to read the barcode of input materials in predefined time intervals or e.g. after each 100th piece.

- In case a wrong input component is detected, MES blocks the work confirmation or it sends an alarm message to a responsible person, or it stops the assembly line completely.

- Sun visor reworks – each disassembled sun visor can return to the assembly workplace, its traceability is preserved due to unique identification of pieces.

- MES drives the rules for controls and data collection from controls, based on internal control plans. MES requires 100% quality control at the quality wall.

- Filling in of partially filled packages – MES monitors, whether partially filled packaging units receive the right type of product inside.

- MES controls the process of label printing at the final operation (quality wall) according to the packaging requirements and the number of produced products (counted automatically from the assembly line). Each final product gets a direct link to a specific packaging unit in MES, resulting in complex traceability of packaging units and individual products.

- MES sends the work confirmations, material consumption, packaging units and more to the SAP system. The MES-finalized packing process is further processed in SAP.

- Last but not least, MES automatically collects and evaluates the data about downtimes. Thanks to automatically induced start of downtime, MES also collects and evaluates micro-downtimes. Based on this data, more accurate evaluation of OEE is achieved across all production equipment.

Improved availability of personnel based on Alarm system

MES based alarms and notifications integrated with a pager switchboard and individual pagers are used as a support tool for operative production control in LUKOV Plast. Pager beats the smartphone in LUKOV Plast. Why? Mostly due to its simplicity, possibility of sharing, long battery life and robustness.

MES based alarm & messaging system is used mainly for:

- Calling operators to the workplace using the production terminal interface (quality, setting, maintenance, logistics…).

- Identification of mismatch type of input component for assembly.

- Notification about delayed production.

- Coming end of a production order.

- Notification about increased NOK rates.

Data processing & evaluation

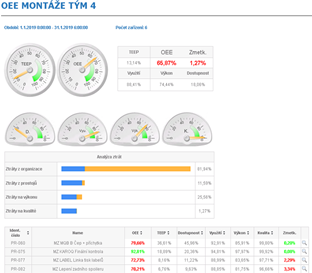

NOK rates, downtime rates and OEE are three critical parameters for evaluation of production performance in LUKOV Plast. It is the task of the MES system to provide unbiased data for objective evaluation of production performance and for long-term strategic management. LUKOV Plast uses three tools provided by MES for a quick overview of the production and its evaluation:

- Visualization screens located directly at the shop floor, providing online overview of the work in progress, quality, OEE, TEEP, availability… MES key users can create their own custom screens with their own preferred data, according to the placement of each screen.

- KPI integrated in MES system – pareto of downtimes, NOK rate, machine availability…

- MES-based Report builder & editor, custom built reports

Fulfilled expectations

LUKOV Plast achieved the following goals by merging technological know-how with the possibilities of MES/MOM PHARIS:

- Each 7 seconds one sun visor leaves the assembly line – that’s blisteringly fast.

- LUKOV Plast is able to control production with high-variability very efficiently (incl. small batch).

- 100% traceability of each sun visor with unique identification.

- Rapid increase of OEE at the assembly line and other workplaces.

- The distribution process of e-documentation is compliant with IATF 16 949 based audits.

- Getting up-to-date online overview of the work in progress.

- Reduction of semi-stock supplies.

- Collection of technological parameters from production equipment.

- Integration of MES/MOM PHARIS with ERP SAP using web services.

Author’s note

Due to its scope, this article does not describe several more workplaces that are included in the production process of sun visors in LUKOV Plast. They are mainly PVC & leather formatting, fully automated check of functions of each sun visor, ultrasonic welding, high-frequency welding and more ...

Martin Urban

The author has been active in the field of Manufacturing Execution Systems for more than 10 years. He works for UNIS, Inc. as the Head of Sales and Marketing Department. UNIS, Inc. develops and implements its own Manufacturing Execution System – MES PHARIS.

English (UK)

English (UK)  Česky (CS)

Česky (CS)