To be successful with MES / MOM implementation, it is important to make the integration with surrounding systems to ensure automated data transfer. This is a demanding part of the implementation, both from a technical and organizational point of view. Many implementation projects will fail because of their unmanaged integration with the surrounding systems. That is why it is very desirable to be well prepared for this part, which can be helped by the following article. Typical systems with which the MES system integrates are as follows:

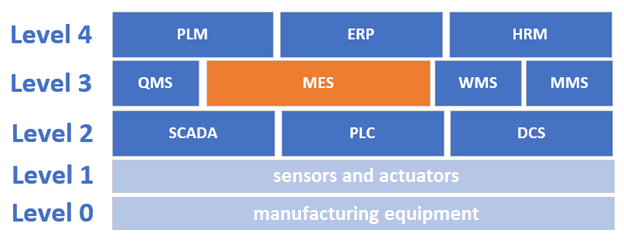

Purdue model

In the 1990s, a reference model for enterprise system architecture was created under the name Purdue Enterprise Reference Architecture – more information on Wikipedia can be found here. This model defines vertical system architecture at 5 levels (Level 0 to Level 4) from physical processes, sensors and controllers, control systems, manufacturing information systems to enterprise business systems. This model was subsequently used as one of the key models in one of the most important standards for MES systems, namely ISA 95, where MES systems are placed at level 3.

Ways of MES / MOM system integration

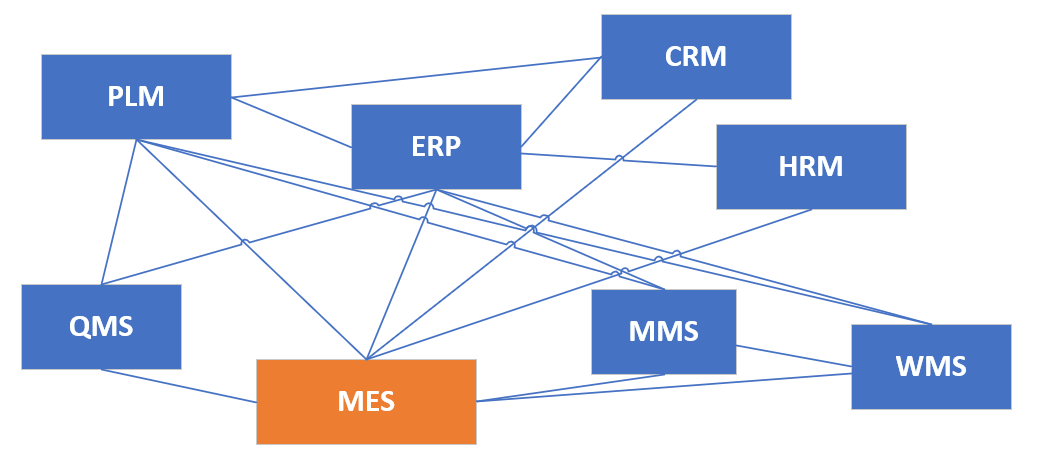

The technical implementation of communication among these systems can take many forms. The historical and still the most common way of interconnecting these systems is the so-called “everyone with everyone” system. This system is in most cases the simplest and cheapest in the implementation phase but is inefficient in terms of sustainability. Sometimes this system is called the “spaghetti system”.

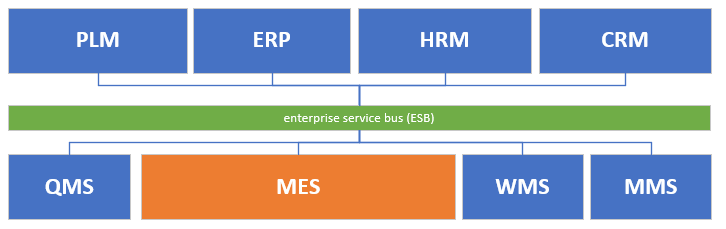

The modern way of interconnection is through the so called ESB (enterprise service bus), or integration service, to which the individual systems connect, provide their data and in turn they can draw the data specified from this bus back. It is called Service Oriented Architecture (SOA). One of the advantages of this approach is the possibility of integrating multiple types of communication protocols. Detailed information and examples of specific ESB products can be found at Wikipedia – Enterprise service bus.

Many types of communications are (or may be) among the above systems. Of course, it always depends on the specific implementation and the situation in an environment. It is also important to mention that in many cases some functionalities are integrated into other systems (typically and ERP system that can take over the role of e.g. WMS, HRM, CRM, etc.). The following are typical communications that can typically occur among these systems:

Typical communication among systems

Communication with systems in Level 4

PLM -> MES

- Production Definition (in some cases Production Definition is transferred from ERP system)

- Required machine settings

ERP -> MES

- Master data (codebooks of persons, equipment, tools, downtime, types of nonconformities, deviations, materials, production definition and others)

- Production requirements (sales orders, production orders)

- Production plan

MES -> ERP

-

Work reporting

Downtime reporting

Material orders requirements

CRM -> MES

-

Request for detailed product information (e.g. based on customer complaint)

MES -> CRM

-

Detailed information of production history

HRM -> MES

-

Availability, level of training

MES -> HRM

-

Operator performance

Communication with systems in Level 3

QMS -> MES

-

Control plan

MES -> QMS

-

Measured values, inspection results, reporting of non-conformities

WMS -> MES

-

Warehouse codebook, stock levels

MES -> WMS

-

Material reservation, stock requirements

CMMS -> MES

-

Maintenance plan, maintenance status

MES -> CMMS

-

Information about the real state of the equipment (number of cycles, production hours, …), maintenance requirements

Communication with systems in Level 2

MES -> PLCs, SCADA, DCS

-

Setting of machine program, blocking the machine, …

PLCs, SCADA, DCS -> MES

-

Information about machine operation (e.g. production cycle, downtime, …), process values (temperatures, pressures, …), alarms, set values

English (UK)

English (UK)  Česky (CS)

Česky (CS)