Although the title of this article says, “What to Remember when we implement the MES System”, its main goal is to introduce you the Manufacturing Maturity Model. I chose the title of the article from the belief that the Manufacturing Maturity Model should lead you to think about what to really remember when the implementation of MES system comes. A detailed description of the Manufacturing Maturity Model is in White Paper # 38, published by MESA International. The purpose of this article is to provide you with basic information about the existence of Manufacturing Maturity Model and how to use it.

We need to introduce two new concepts before we say what the Model of Manufacturing Maturity is. It is about:

- Manufacturing Business Domains

- Manufacturing Maturity Level

Manufacturing Business Domains

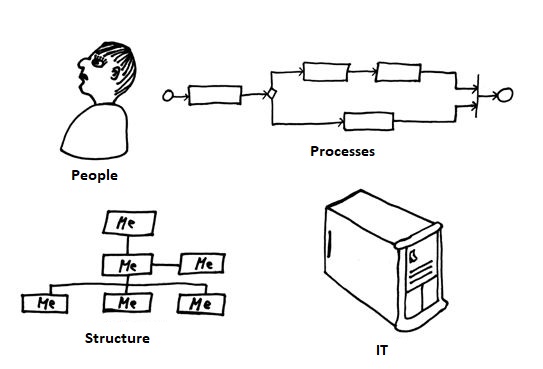

The MESA organization defines four basic production areas that we should pay attention to. These are:

- Processes,

- People (Abilities and Experience, Culture and Behavior, Benefits,…),

- Structure (Responsibility, Authority, Role) and

- IT (Applications, Data, Infrastructure).

Manufacturing Maturity Levels

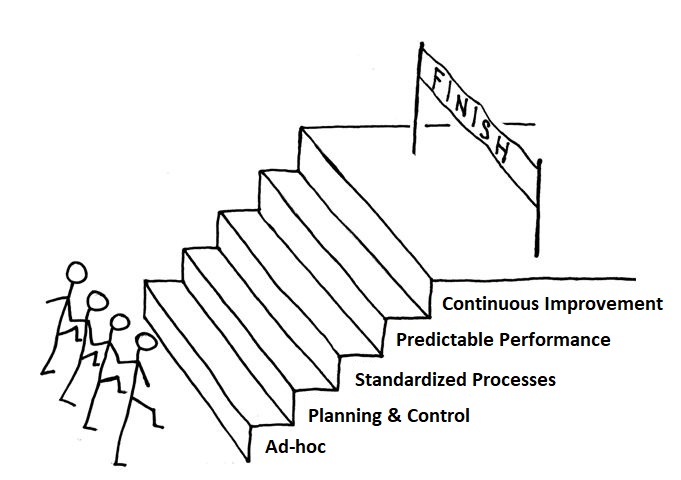

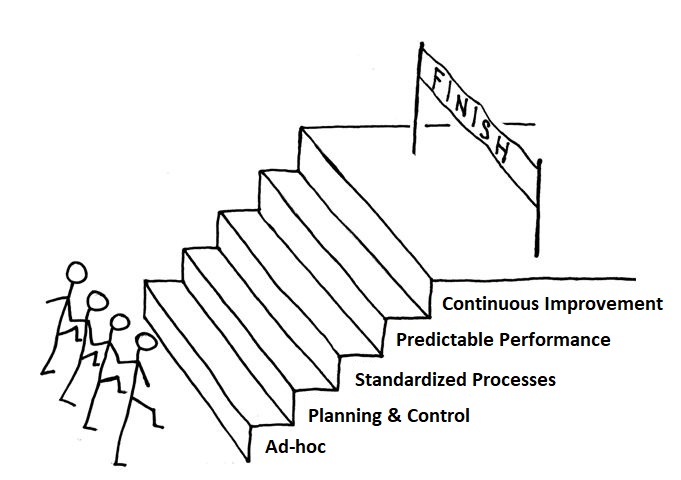

The manufacturing maturity model defines five basic levels of manufacturing maturity. It is about:

- Ad-hoc

- Planning & Control

- Standardized Processes

- Predictable Performance

- Continuous Improvement

These reflect the degree of maturity of the individual manufacturing areas described above. The manufacturing company should internally define each of the individual levels. Typically, this definition should be part of Manufacturing Transformation Strategy, but we will discuss this topic in a separate article. Generally, these definitions contain criteria that can be used to assess the level of maturity.

Manufacturing Maturity Model

The main idea of the Manufacturing Maturity Model is to use the four basic manufacturing areas (defined above) and define their level of maturity. Based on this definition, we then try to get as high as possible in each manufacturing area (stairs in the picture), but with the condition of maintaining the same level of maturity for each manufacturing area. When implementing a new MES / MOM system in your enterprise, you should always consider your level of manufacturing maturity in all areas. If your Processes are at the “Ad-hoc” level and other areas are at the “Planning and Management” level, it would not be efficient to invest in IT. This investment would only increase the gap between Processes and IT.

Different maturity levels

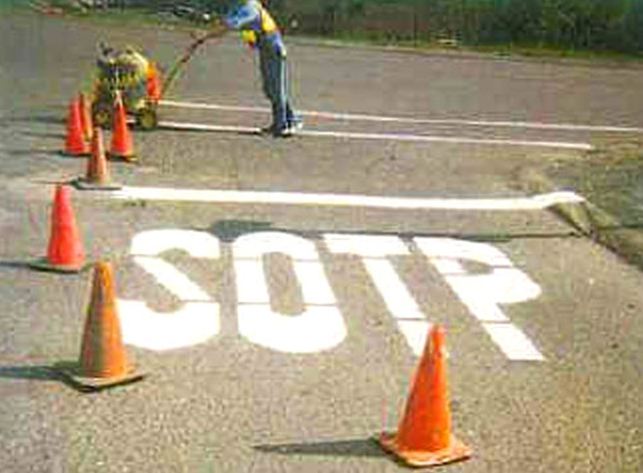

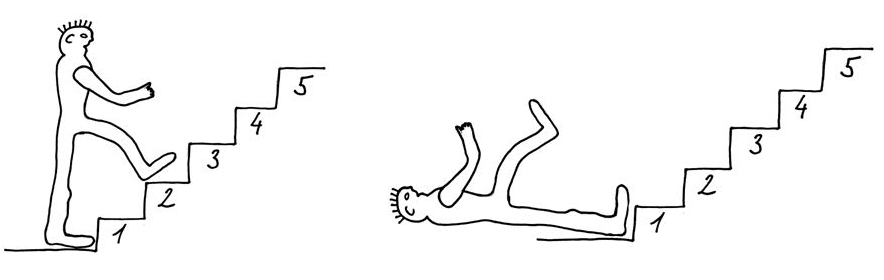

The four Manufacturing Areas shown in the figure as 4 characters must act as a team in your production! This page gives a small example explaining the problem that arises when different manufacturing areas are at different levels of development. The road in the picture is at imaginary level 1 and the car at level 5. When you buy a new car, you should consider the quality (maturity level) of the road on which you will drive this car. There is a high probability that you will not get the anticipated driving experience with the new Mustang on the road shown in the picture below. And the same goes for production. You won't get the expected benefits with an excellent MES system if you have very weak processes, structure and people.

Consider your capability

There is a long way to perfection. At the beginning, you should identify your “status quo”. You should then devote the most effort to aligning all manufacturing areas that affect your production. It is important to make changes step by step. If you are not convinced that you want to implement a change in your production, or if you feel that you are not ready for it, DO NOT do it! You will only lose your time and money. Each of us knows that it is possible to cross more than one stair at once. But each of us also knows that it can cause a fall and subsequent long recovery. It also hurts too. And if this happens to you in production, it can cost you a lot of money.

At what level do you think you are?

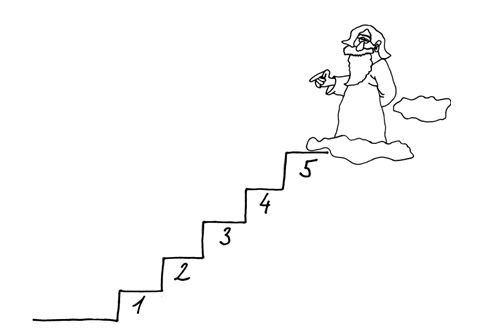

We can imagine that there are five imaginary stairs to heaven - the "manufacturing heaven" of course. Anyone who wants to approach the sky has to work hard and be well prepared at every step leading there. And you need to climb together as a team. Try to think about the level of your business. Think about it thoroughly and be strict on yourself. Think about all the mentioned production areas and place them separately on imaginary stairs. You will then see if all of them are on the same step. This should be a warning to you where to invest your money.

So, what to remember?

As we have seen in the previous part of this article, the MES / MOM system is only one part of the whole. The company management should remember all fundamental manufacturing areas and try to keep them at the same level of maturity.

Look from above

Do not be too focused on detail and try to consider all circumstances from above. If you are lost in detail, it is very likely that you will miss the main idea. It can be assumed that the man in the picture wanted to do his job well. But the impossibility to look at his work from above prevented him from doing so.

English (UK)

English (UK)  Česky (CS)

Česky (CS)